Current Price:

$14.95

About Concrete Etch

Liquid Rubber Concrete Etch contains a granular base, that is mixed with warm water to create an etching solution suitable for removing Laitance and Efflorescence in preparation of concrete, stone, and masonry surfaces prior to coating. The life of any coating is dependent on adhesion to a clean, sound surface. Etching the surface removes contaminants and minutely roughens the surface, as well a neutralizing the PH of the concrete and masonry, to ensure strong adhesion and a long-lasting coating.

Real homeowners using Concrete Etch

Easy to use

"Received a quick response from Support and they answered all questions I had."

Frank HelmickConcrete Etch

How to Use Concrete Etch

Essential Resources for Your Project

-

Application Guide

Decks & Balconies

Detailed steps to complete your project.

Application Guide

Decks & Balconies

Detailed steps to complete your project. -

Application Guide

Ponds

Detailed steps to complete your project.

Application Guide

Ponds

Detailed steps to complete your project. -

Application Guideline

Interior Basement

Detailed steps to complete your project.

Application Guideline

Interior Basement

Detailed steps to complete your project. -

Application Guide

Planter Box

Detailed steps to complete your project.

Application Guide

Planter Box

Detailed steps to complete your project. -

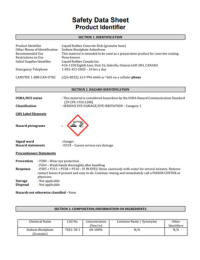

Safety Data Sheet

Concrete Etch

Stay informed and safe throughout your project.

Safety Data Sheet

Concrete Etch

Stay informed and safe throughout your project. -

Technical Data Sheet

Concrete Etch

Get the technical details you need.

Technical Data Sheet

Concrete Etch

Get the technical details you need. -

Coverage

Concrete Etch

Coverage

Concrete Etch

Concrete Etch Gallery

See how homeowners are using Concrete Etch

Questions About Concrete Etch

-

Is Concrete Etch Safe?

-

What surfaces require concrete etch?

-

How long does it take to get my order once I have placed it?

-

Can I get a First Purchase discount?

Need some help?

Our team of experts are standing by to help make sure your project is a success.

Why Liquid Rubber?

-

Free Shipping Over $49.95

-

Free Returns

Coverage Calculator

Show results in:

Product:

Size of Project:

Estimate the size of your project space in sq ft.

Type of Project: