Looking for a reliable solution to protect your home from water damage? Look no further! Liquid Rubber Foundation Sealant is the ultimate waterproofing membrane that goes beyond just slowing down water—it completely stops it in its tracks. This advanced sealant is painted on and cures into a highly elastic membrane with 900% elongation, ensuring long-lasting protection even in the most challenging conditions.

What sets Liquid Rubber apart? It's eco-friendly, non-toxic, and safe for both indoor and outdoor use, including confined spaces. No special protective equipment is needed, making it a hassle-free option for DIYers and professionals alike. Originally developed for demanding commercial and industrial applications, this top-tier product is now available for your home projects.

Everything you need to seal your exterior foundation. Add or remove items as you need them!

Application Guideline

Interior Basement

Detailed steps to complete your project.

Application Guideline

Interior Basement

Detailed steps to complete your project. Application Guide

Exterior Foundation

Detailed steps to complete your project.

Application Guide

Exterior Foundation

Detailed steps to complete your project. Application Guide

Shower Liner

Detailed steps to complete your project.

Application Guide

Shower Liner

Detailed steps to complete your project. Application Guide

Planter Box

Detailed steps to complete your project.

Application Guide

Planter Box

Detailed steps to complete your project. Supply Checklist

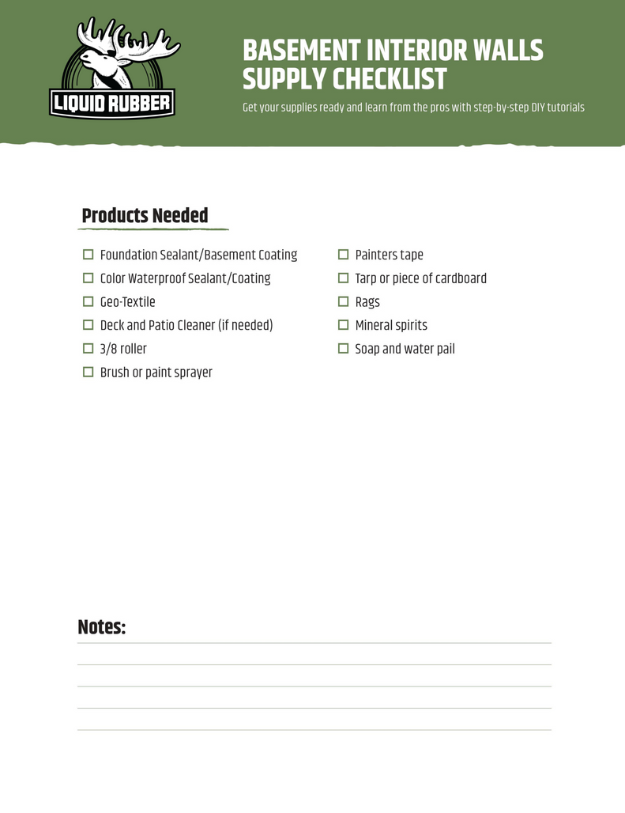

Interior Basement

Make sure you have everything before you start.

Supply Checklist

Interior Basement

Make sure you have everything before you start. Supply Checklist

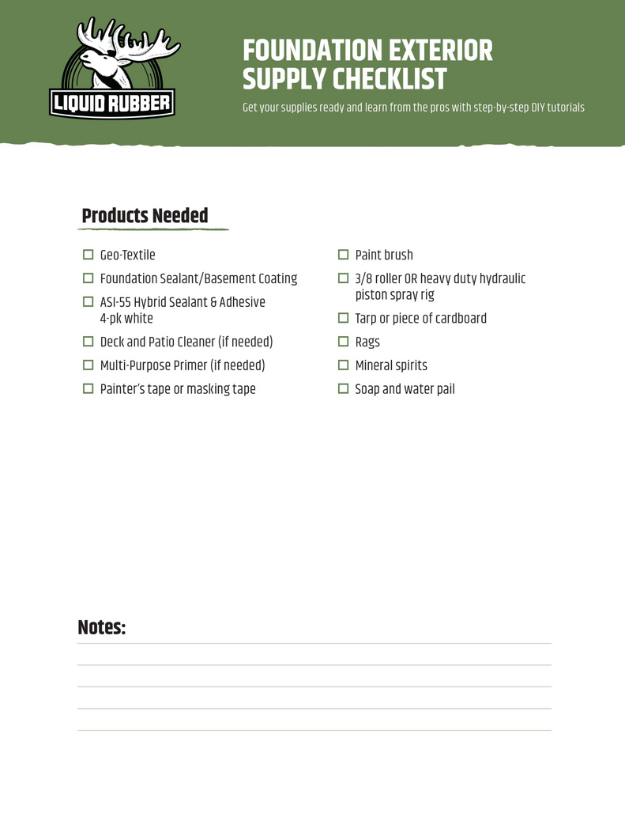

Exterior Foundation

Make sure you have everything before you start.

Supply Checklist

Exterior Foundation

Make sure you have everything before you start. Supply Checklist

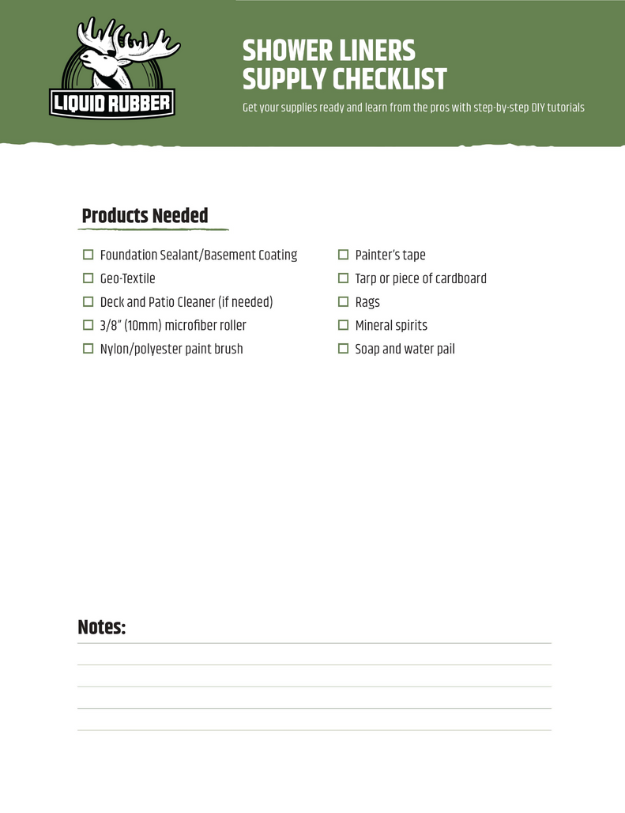

Shower Liner

Make sure you have everything before you start.

Supply Checklist

Shower Liner

Make sure you have everything before you start. Supply Checklist

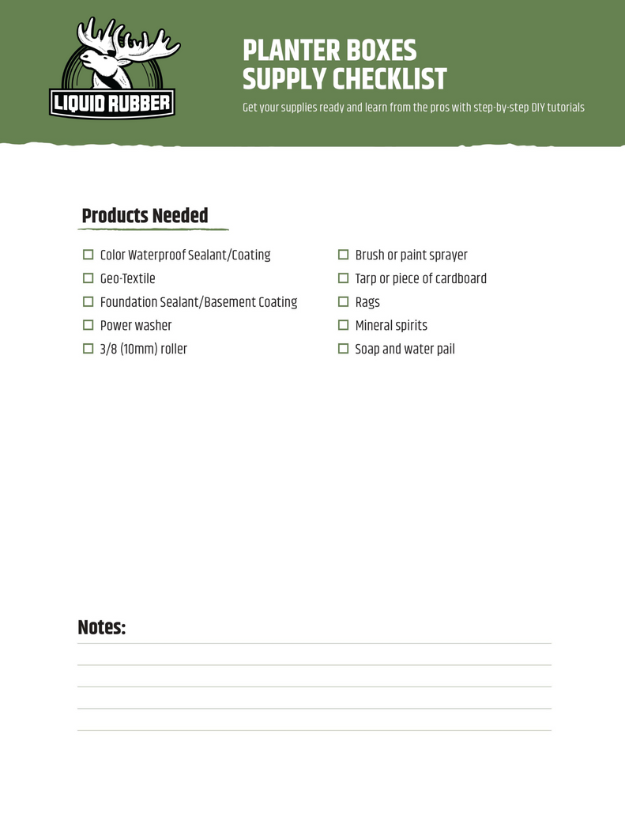

Planter Box

Make sure you have everything before you start.

Supply Checklist

Planter Box

Make sure you have everything before you start. SDS

Foundation Sealant

SDS

Foundation Sealant

Technical Data Sheet

Foundation Sealant

Get the technical details you need.

Technical Data Sheet

Foundation Sealant

Get the technical details you need. Coverage

Foundation

Coverage

Foundation

Our team of experts are standing by to help make sure your project is a success.