Ready to upgrade your RV adventures? Look no further than Liquid Rubber RV Roof Coating, the ultimate solution for all RV roof types - EPDM, TPO, aluminum, or fiberglass. Transform your roof in just one weekend with our easy DIY RV roof repair system. Even if you're a novice, you'll find it simple to apply over a weekend. With over 20 years of industry expertise, our products are backed by a 10-year guarantee, ensuring your roof stays leak-free and watertight. Trust us to guide you through every step and join a community of satisfied RV owners.

A well-maintained roof means comfort, cooler temps inside, and a higher resale value, making your RV a cozy, reliable, and stylish home on wheels. With Liquid Rubber RV Roof Coating, you're investing in quality and long-term satisfaction. Hit the road with confidence, knowing your roof is ready for any adventure.

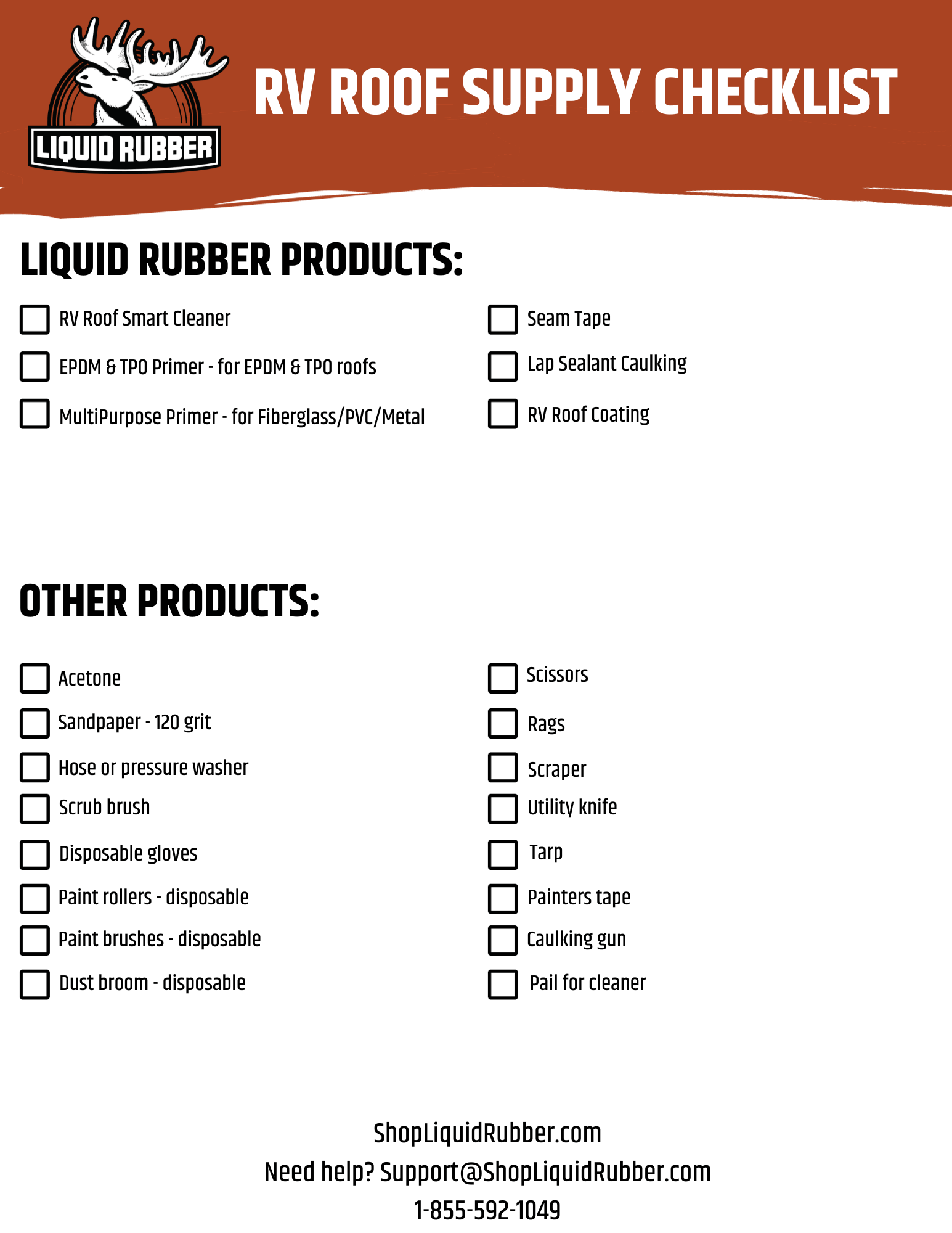

Everything you need to seal your RV Roof. Add or remove items as you need them!

Application Guide

RV Roofs

Detailed steps to complete your project.

Application Guide

RV Roofs

Detailed steps to complete your project. Application Guide

RV Lap Sealant

Detailed steps to complete your project.

Application Guide

RV Lap Sealant

Detailed steps to complete your project. Product Supply Checklist

RV Roofs

Make sure you have everything before you start.

Product Supply Checklist

RV Roofs

Make sure you have everything before you start. Safety Data Sheet

Stay informed and safe throughout your project.

Safety Data Sheet

Stay informed and safe throughout your project. Technical Data Sheet

Get the technical details you need.

Technical Data Sheet

Get the technical details you need. Coverage

RV Roof Coating

Coverage

RV Roof Coating

Our team of experts are standing by to help make sure your project is a success.