Your RV roof protects you on every adventure, but cracks around vents, peeling seams, or interior water stains are warning signs you can't ignore. You worry about leaks causing expensive damage, dealer repair costs, and whether you can tackle it yourself. But what if sealing those leaks was actually simple?

Liquid Rubber RV Lap Sealant makes waterproofing your RV roof effortless. Using a Caulking gun to apply directly to seams, vents, skylights, and roof joints for an instant seal. This self-leveling, moisture-curing formula creates a flexible, waterproof barrier that moves with your RV through temperature changes and road vibrations. Say goodbye to costly repairs and hello to a protected, watertight RV with Liquid Rubber RV Lap Sealant—the DIY-friendly solution that seals leaks.

Application Guide

RV Lap Sealant

Detailed steps to complete your project.

Application Guide

RV Lap Sealant

Detailed steps to complete your project. Application Guide

RV Roofs

Detailed steps to complete your project.

Application Guide

RV Roofs

Detailed steps to complete your project. Safety Data Sheet

RV Lap Sealant

Stay informed and safe throughout your project.

Safety Data Sheet

RV Lap Sealant

Stay informed and safe throughout your project. Technical Data Sheet

RV Lap Sealant

Get the technical details you need.

Technical Data Sheet

RV Lap Sealant

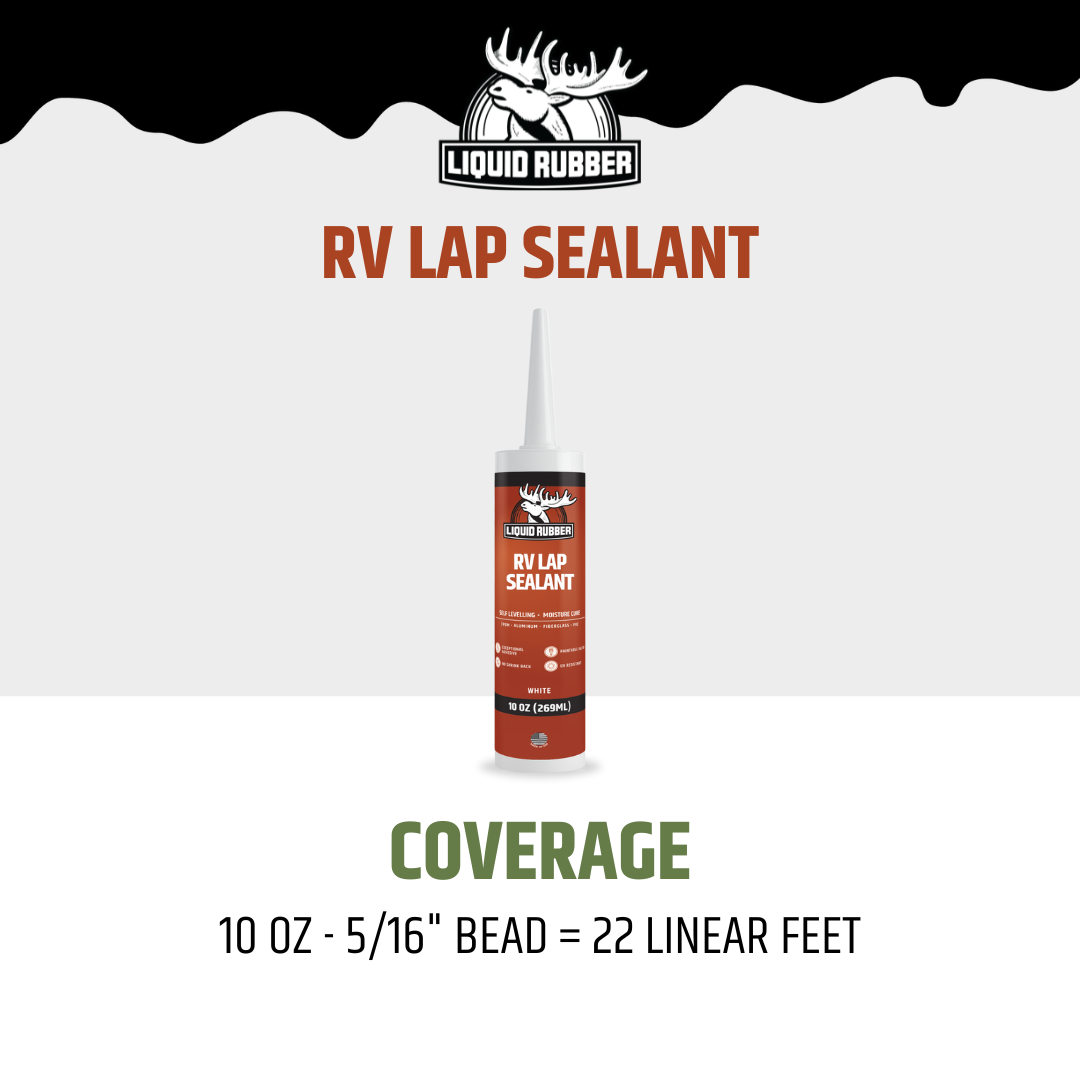

Get the technical details you need. Coverage

RV Lap Sealant

Coverage

RV Lap Sealant

Our team of experts are standing by to help make sure your project is a success.