Time to Complete

48 hours

Difficulty Level

Beginner

Products Needed

5

Project Overview: Achieve Long-Lasting Protection for Your RV Roof

Over 100,000 RV owners have successfully completed their roof sealing projects with Liquid Rubber RV Roof Repair Sealant. Whether you're tackling annual maintenance, repairing specific damage, or fully restoring your roof, Liquid Rubber’s products ensure a durable, waterproof finish that lasts.

Scroll down to learn more 👇

10 Year Warranty

Customer Success Stories: Real Results from Real RV Owners

Enter the length of your RV

Subtotal

Build Your RV Roof Kit

Everything you need to seal your RV Roof. Add or remove items as you need them!

Subtotal

Choose Primer

EPDM & TPO Primer

"Used for EPDM and TPO Roofs"

Multipurpose Primer

"Used for Fiberglass, Metal/Aluminum and PVC/Vinyl Roofs"

How to Seal Your RV Roof: Step-by-Step Project Walkthrough

Essential Resources for Your Project

-

Application Guide

RV Roofs

Detailed steps to complete your project.

Application Guide

RV Roofs

Detailed steps to complete your project. -

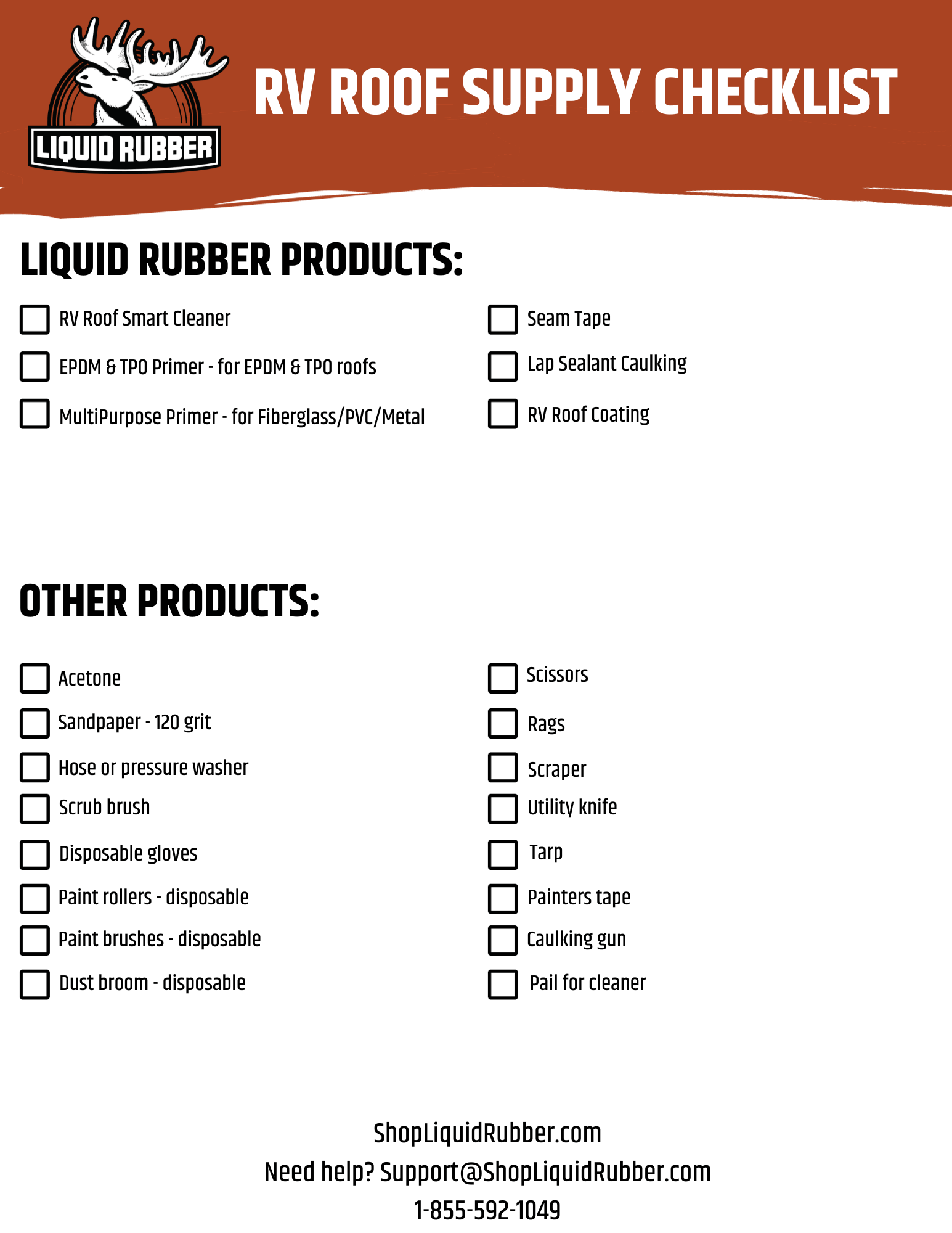

Product Supply Checklist

RV Roofs

Make sure you have everything before you start.

Product Supply Checklist

RV Roofs

Make sure you have everything before you start. -

Technical Data Sheet

Get the technical details you need.

Technical Data Sheet

Get the technical details you need. -

Safety Data Sheet

Stay informed and safe throughout your project.

Safety Data Sheet

Stay informed and safe throughout your project.

Project Steps

-

Determine Roof Material

-

Inspect RV Seams, Joints and Roof

-

Preparation & Cleaning

-

Seal RV Roof Vents & Seams

-

Apply the Coating

-

Weather & When to Apply

-

Helpful Tips

RV Roof Sealing Gallery

Check out customer-submitted photos of successful RV roof sealing projects completed with Liquid Rubber. Get inspired and see the quality results others have achieved:

Frequently Asked Questions: Your RV Roof Sealing Project

Need some help?

Our team of experts are standing by to help make sure your project is a success.

Why Liquid Rubber?

-

Free Shipping Over $49.95

-

Free Returns

-

10 Year Warranty

-

Over 100,000 RVs Protected