Liquid Rubber Cool Foot Deck Coating is a high-performance, acrylic, elastomeric coating that reduces heat transfer by up to 35% compared to regular paint. The Cool Foot Deck Coating cures into a durable, seamless, colored waterproof membrane. Contains no solvents, is non-toxic, VOC-free, and is non-flammable. The cured membrane has excellent solar reflectivity and UV stability.

Everything you need to seal your deck. Add or remove items as you need them!

Application Guide

Decks & Balconies

Detailed steps to complete your project.

Application Guide

Decks & Balconies

Detailed steps to complete your project. Product Supply Checklist

Make sure you have everything before you start.

Product Supply Checklist

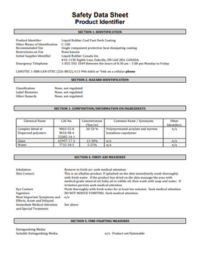

Make sure you have everything before you start. Safety Data Sheet

Cool Foot Coating

Stay informed and safe throughout your project.

Safety Data Sheet

Cool Foot Coating

Stay informed and safe throughout your project. Technical Data Sheet

Cool Foot Coating

Get the technical details you need.

Technical Data Sheet

Cool Foot Coating

Get the technical details you need. Coverage

Cool Foot

Coverage

Cool Foot

Our team of experts are standing by to help make sure your project is a success.