INSPECTION

Improperly prepared surfaces can result in the reduction of the service life and performance of the membrane coating. A thorough inspection of the substrate prior to beginning work should be performed to ensure adhesion and the integrity of the coating. Liquid Rubber products must be installed on a sound substrate. How to perform an adhesion test.

*Performing a moisture test is recommended. Although a surface may appear dry, internal moisture can become trapped under a coating and would sacrifice the integrity of the structure. For Wood - click HERE. For Concrete - click HERE

- Surface must be free of voids, low/ponding areas and irregularities.

- Drains, gutters, scuppers, etc. must be in good condition and functioning properly.

- If an existing coating is present, determine the compatibility of the coating to Liquid Rubber products by coating a small test area.

*Do not apply to silicone or coal tar [Liquid Rubber Silicone Roof Coating can be applied to most silicones.]

Mod-Bit, EPDM, TPO, PVC, Fiberglass - Look for cracked surfaces, failed seams, pulling away from roof elements like vents, etc. *A moisture test for single ply can be performed by conducting an Infrared Moisture Scan

Concrete - Look for cracks, spalls, and honeycombing and repair. Look for laitance. A moisture test is recommended Wood - Check for protruding nails/screws and splinters; countersink or remove and fill.

Wood must be adequately dry. Perform a moisture test. Moisture content needs to be below 15% before coating.

Spray Polyurethane Foam (SPF) - SPF should be completely dry and free of defects. The elastomeric topcoat should be well bonded. Loose, flaky material should be removed, blisters cut out, pinholes, ponding/low area’s and light spots repaired. Rasp oxidized/weathered foam (this may appear as pitting or as a rusty or patchy color). SPF repairs should be complete and fully cured prior to waterproofing application.

PREPARATION & CLEANING:

Liquid Rubber roofing products must be installed on a clean, dry, and structurally sound surface that is free of sharp edges, dirt, debris, oil, grease, coal tar, mastics, flaking paint, silicone, or other contaminants.

- Mod-Bit - clean using compressed air, a sweeper, or pressure washer to provide a clean bonding surface. (be cautious when introducing water, as the surface must be completely dry for application and cure).

- Wood - use Liquid Rubber Deck and Patio cleaner to remove contaminants and brighten the wood. Rinse thoroughly and allow to dry completely.

- Concrete - use Liquid Rubber Concrete Etch to remove laitance and create profile on the concrete. Rinse thoroughly and allow to dry completely.

- SPF - rasp oxidized/weathered or contaminated foam (this may appear as pitting or as a rusty or patchy color). SPF repairs should be complete and fully cured prior to waterproofing application.

- EPDM - Clean with Liquid Rubber RV Roof cleaner to remove contaminants. Rinse thoroughly and allow to dry completely.

- TPO, PVC and Fiberglass - roughen the surface with 120 grit sandpaper. Clean to remove debris. Rinse thoroughly and allow to dry completely.

Use masking tape for areas not to be painted and remove while the Primer/Coating is still wet. Apply masking tape for each coat.

Application Guideline

Flat/ Low Slope Roof

Detailed steps to complete your project.

Application Guideline

Flat/ Low Slope Roof

Detailed steps to complete your project. Application Guideline

Interior Basement

Detailed steps to complete your project.

Application Guideline

Interior Basement

Detailed steps to complete your project. Application Guide

Metal Roof

Detailed steps to complete your project.

Application Guide

Metal Roof

Detailed steps to complete your project. Safety Data Sheet

Color Sealant

Stay informed and safe throughout your project.

Safety Data Sheet

Color Sealant

Stay informed and safe throughout your project. Technical Data Sheet

Color Sealant

Get the technical details you need.

Technical Data Sheet

Color Sealant

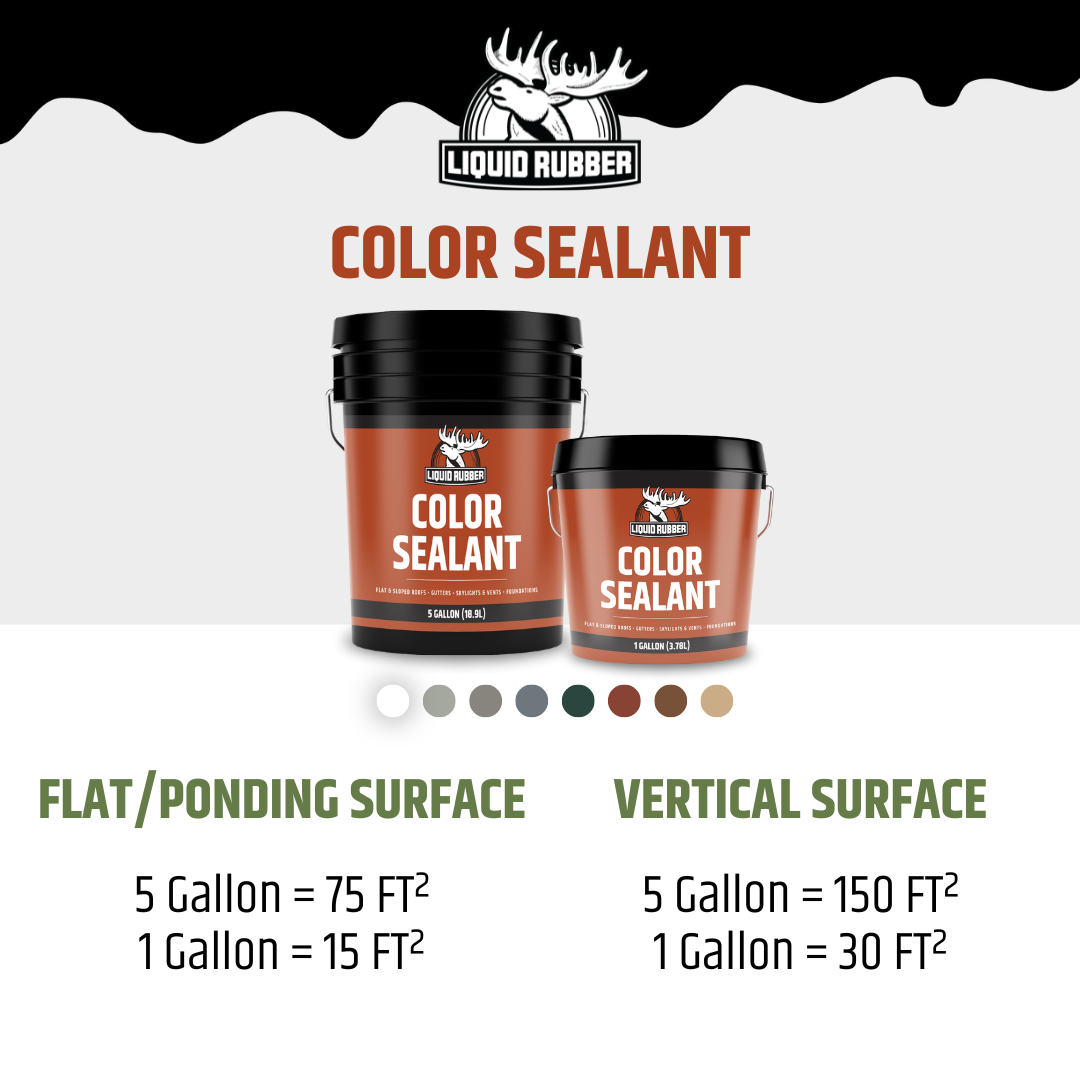

Get the technical details you need. Coverage

Color Sealant

Coverage

Color Sealant